Textile insulation and insulating sleeves

RBS Textile Insulation and Insulation Sleeves made from high temperature resistant fabrics are used in a wide range of industries for 2 main reasons.

- Material | Material

- Tarapaulin | Glass fabric | Aramid | Silicate fabric

-

Energy Efficiency

To increase energy efficiency where insulation is not possible.

Contact Protection

As contact protection to increase work safety.

Long Service Life

We rely on materials that have been tried and tested over many years for long service life.

Properties

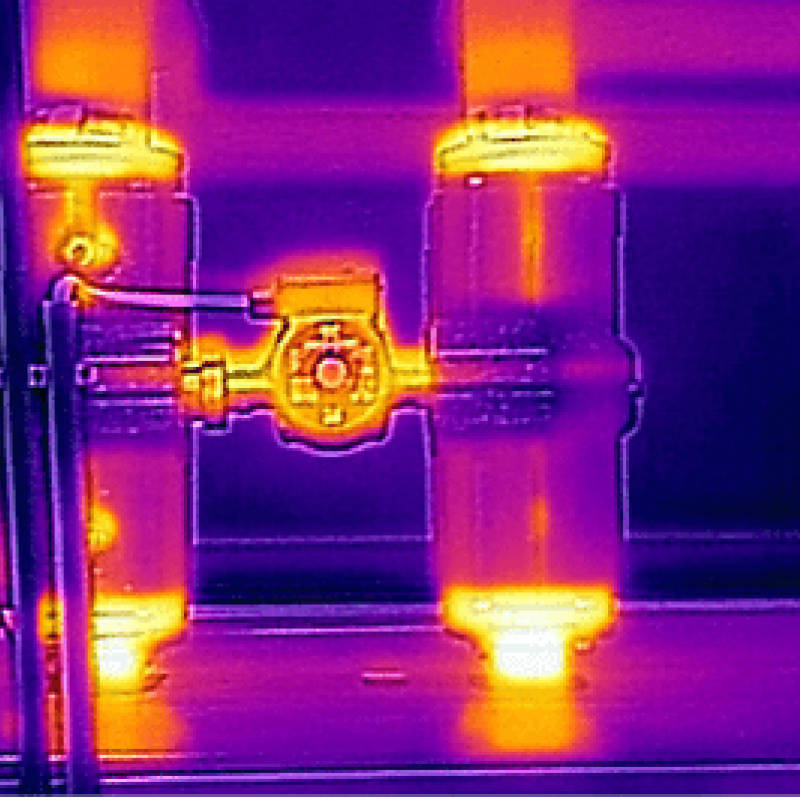

RBS Textile Insulation and Insulation Sleeves made from high-temperature resistant fabrics are used in a wide range of industries for 2 main reasons: to increase energy efficiency in areas where other materials cannot be used for insulation and as protection against contact to increase safety at work.

Whether in pipeline construction, for the manufacture of large and small engines, or in exhaust gas treatment, RBS technical assemblies stand for many years of service life and, if necessary, can be replaced with innovative lashing and tensioning systems without great effort. For these products, we use the same materials that have been tried and tested over many years as for our expansion joints or bellows and extend these with zip fasteners, hook fasteners, or Velcro fasteners to enable quick and easy assembly.

Advantages

- energy efficiency

- contact protection

- Increase in occupational safety

- Long service life

- Materials tested over many years

- Various closures

- Quick and easy assembly

Installation Fabric types

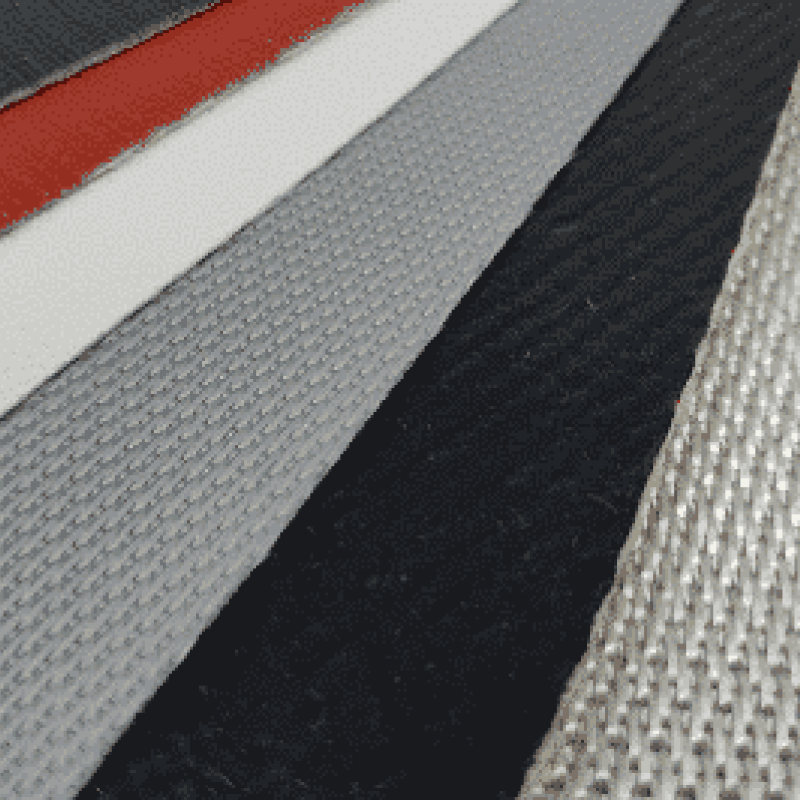

Tarpaulin: suitable for temperatures up to 70 ° C, is often used as dust protection

Fiberglass fabric: either with double-sided PU or silicone coating is suitable for a temperature range of 250 - 550 ° C.

Aramid fiber fabric: with aluminium coating suitable for temperatures up to approx. 350°C, has high tensile strength

Silicate fiber fabric: with aluminum coating or vermiculite coating for temperatures up to about 1000 ° C, is often used in steel mills and foundries due to the temperature resistance

-

RBS Kompensator GmbH

In 2009, at the request of many customers, RBS Kompensator GmbH was founded as the 100% sister company of KS Kneissl & Senn Technologie GmbH under Senn Beteiligungs GmbH.

Building on the existing know-how about temperature-resistant high-performance fabrics, these began to be manufactured as individual pieces in the form of soft-material compensators by hand in Erl. Gradually, various sewing and welding machines were acquired in order to be able to produce all common shapes (round / square / round on square etc.) in the best possible way.

Together with our team we try to live the idea of the "One Stop Shop" and make sometimes impossible things possible according to our motto: "Viribus unitis - with united forces".