Fabric Expansion Joints

Expansion joints are generally speaking elastic components that are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc.) or for compensating the installation of plant components.

-

Temperature Resistance

Depending on the material, temperature resistance up to 1000 °C.

Mounting Compensation

For mounting compensation of system components.

Strain Absorption

Absorption of pipeline expansions and vibrations.

Properties

Expansion joints are generally speaking elastic components that are suitable for absorbing pipeline expansions and vibrations (e.g. due to heat, etc.) or for compensating the installation of plant components. The design is decisively determined by the medium, pressure, temperature, size and direction of the expansion to be absorbed. Soft-material or fabric compensators are line and duct components made of technical fabrics or elastomers. They are used to compensate for mechanical misalignment as well as to reduce sound and vibration. The fabric expansion joint is either fixed by means of clamping strips or - for lower loads - attached to the pipeline by means of tensioning straps.

Advantages

- Mounting compensation of system components

- Absorption of pipeline expansions

- vibration absorption

- Temperature resistant

- Produced in-house

- Made from materials that have been tried and tested over many years

- Long service life

Materials | Moulds

The material selection is initially based on the tightness requirement and is determined by the resistance to medium, temperature and mechanical load capacity. Depending on the temperature and type of medium, different basic designs of fabric expansion joint are used. Thus, temperatures of up to 1000 °C can be permanently controlled. Materials made of various fabrics (polyester, aramid, glass, high-temperature glass, silicate glass, wire-reinforced fabrics) together with coatings (neoprene, hypalon, EPDM, silicone, fluororubber, PTFE) as well as mats (insulation layers) and foils (neoprene, hypalon, EPDM, silicone, fluororubber, PTFE, aluminium, stainless steel) are available for the layer structure.

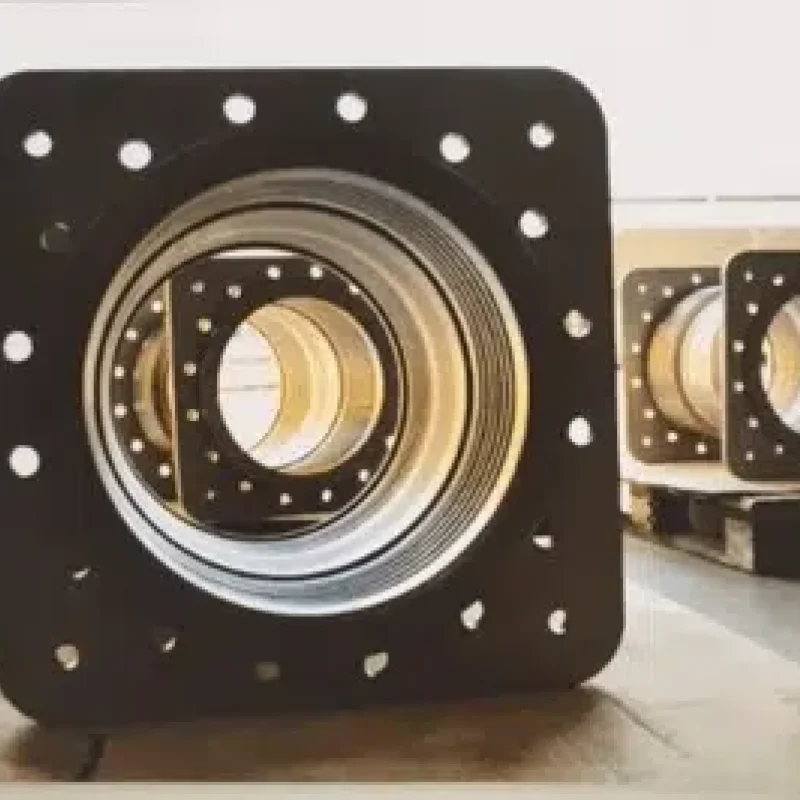

In terms of shape, round, square and rectangular as well as mixed shapes from round to square are possible. In terms of length, the largest expansion joints manufactured to date were 40m as an open belt expansion joint. Of course we also offer all necessary accessories such as closing accessories, glue, insulating pads, tension clamps, blind flanges, backing strips, glue, etc.

Application

Depending on the application, soft-material compensators are manufactured in single-layer or multi-layer design. Due to the multi-layer design, different functions, e.g. insulation, sealing, pressure surge behaviour, etc. can be combined according to the specific requirements. Compared to metal expansion joints, fabric expansion joints are characterized by low weight and low reaction forces. Therefore, fabric expansion joints are particularly suitable for large dimensions at low operating pressures and gaseous media (air, exhaust gas, flue gas).

We manufacture RBS fabric expansion joints and soft-material expansion joints for a wide variety of applications according to your requirements and special circumstances.

Download installation and closing instructions RBS fabric compensator Bandform.

-

RBS Kompensator GmbH

In 2009, at the request of many customers, RBS Kompensator GmbH was founded as the 100% sister company of KS Kneissl & Senn Technologie GmbH under Senn Beteiligungs GmbH.

Building on the existing know-how about temperature-resistant high-performance fabrics, these began to be manufactured as individual pieces in the form of soft-material compensators by hand in Erl. Gradually, various sewing and welding machines were acquired in order to be able to produce all common shapes (round / square / round on square etc.) in the best possible way.

Together with our team we try to live the idea of the "One Stop Shop" and make sometimes impossible things possible according to our motto: "Viribus unitis - with united forces".